license tests by hardness|hardness testing instrument : distributor ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir . The report presents a detailed analysis of the following key players in the global autoclaved aerated concrete (AAC) market, looking into their capacity, market share, and latest developments like capacity expansions, plant turnabouts .

{plog:ftitle_list}

After about 2 months, both MES and MOPS buffer turn yellow at room temperature by oxidation. The same thing happens in the autoclave. Yellow MES and MOPS is an oxidized form of the .

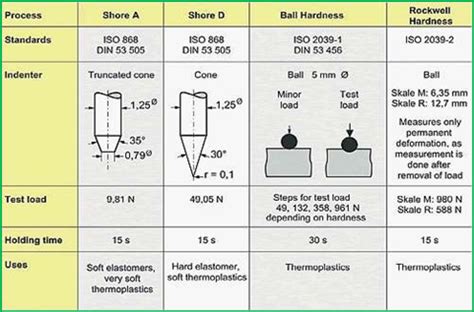

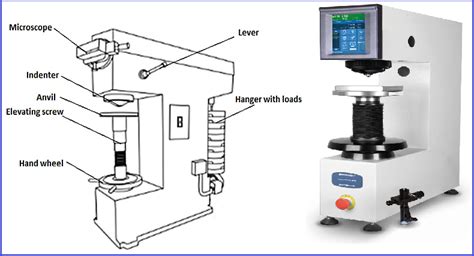

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality . A Rockwell hardness tester. The Rockwell scale is a hardness scale .

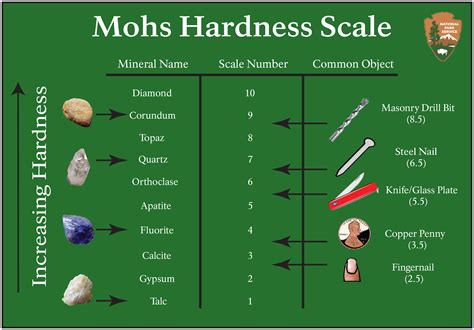

Hardness comparison. A variety of hardness -testing methods are available, .

ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir .The best hardness test method and corresponding load depend on the material to be tested, .

A hardness test is typically performed by pressing a specifically dimensioned and loaded object . Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality control of a manufacturing or hardening process.

standards for hardness testing

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1]

Hardness comparison. A variety of hardness -testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels.ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .

15 May. The ability of a material to resist permanent indentation is known as hardness. It is an empirical test, rather than material property. In order to define different hardness values for the same piece of material, there are several types of hardness tests.

The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica- tion, and the customer requirements. After process of elimination, there are often only a few options left.

hardness testing scale

A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by measuring the depth of indenter penetration or by measuring .

Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Advertisement.Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness.

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well as quality control of a manufacturing or hardening process.

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1]Hardness comparison. A variety of hardness -testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels.

ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .15 May. The ability of a material to resist permanent indentation is known as hardness. It is an empirical test, rather than material property. In order to define different hardness values for the same piece of material, there are several types of hardness tests.The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica- tion, and the customer requirements. After process of elimination, there are often only a few options left.A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by measuring the depth of indenter penetration or by measuring .

hardness testing process

Materials are tested using various methods, with each test expressing hardness using its own arbitrarily defined scale. In this article we shall explore five of the most common test methods for measuring the hardness of a material, how they differ and in which situations they are most suitable. Advertisement.Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness.

krautkramer microdur portable hardness tester

krautkramer mobile uci hardness tester mic 10

Oven brisket is an approachable way to cook Texas-style brisket without any fancy cookware or appliances. Smoked brisket is known for its .

license tests by hardness|hardness testing instrument